Smart Manufacturing System

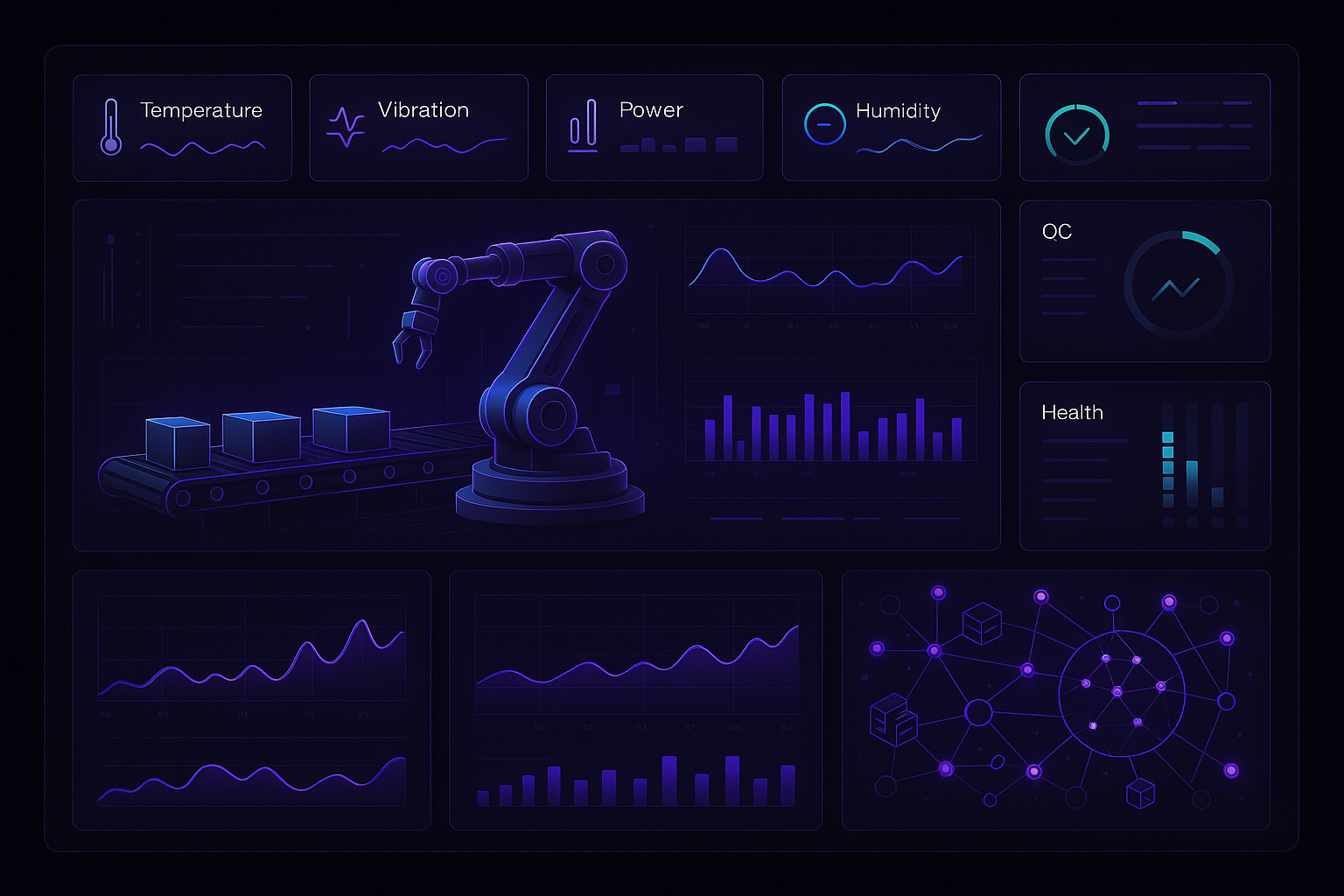

Integrated AI capabilities into existing manufacturing systems for predictive maintenance, quality control, and supply chain optimization.

Project Overview

We integrated advanced AI capabilities into an existing manufacturing system to enable predictive maintenance, quality control, and supply chain optimization. The system uses IoT sensors to collect real-time data from manufacturing equipment and processes. The AI-powered predictive maintenance system analyzes equipment data to predict potential failures before they occur, reducing downtime and maintenance costs. Quality control is enhanced through computer vision systems that automatically inspect products for defects. Supply chain optimization uses machine learning to forecast demand, optimize inventory levels, and improve logistics. The system provides real-time dashboards showing production metrics, equipment health, quality statistics, and supply chain status.

Technologies Used

Results & Impact

Why This Mattered

ManufacturePro was experiencing costly downtime and quality issues. Without predictive maintenance and AI quality control, they couldn't compete on efficiency. The integrated AI system didn't just reduce costs—it transformed their entire manufacturing process, making them a leader in smart manufacturing.

“What would have happened without this solution? The client would have continued facing the same challenges—slower growth, higher costs, and competitive disadvantages. This project wasn't just about building software—it was about transforming their business.”

Related Services

Explore the services we used to deliver this project:

AI Integration Services

Infuse intelligence into your existing systems. Add AI capabilities without rebuilding from scratch.

Learn MoreData Analytics & Business Intelligence

Turn data into insights. Custom dashboards, data warehousing, and business intelligence solutions that drive decisions.

Learn MoreCloud Solutions & DevOps

Migrate to the cloud and optimize your infrastructure. AWS, Azure, and GCP solutions with DevOps best practices.

Learn More